Ep.6: The Open Source Ventilator Project with Dugan Karnazes and Nadim Conti

This week we are joined by Dugan Karnazes, CEO of design firm Velocity Research and Nadim Conti, System & Electronic Designer at the Italian National Institute for Nuclear Physics and Collaboration Member at CERN to talk about about their involvement with the Open Source Ventilator (OSV) Project. We discuss how COVID-19 disrupted their normal work lives, how OSV evolved, the importance of the project being open source, and more.

Official website for the Open Source Ventilator project: https://opensourceventilator.ie/

Assembly of the Open Source Ventilator boards by Worthington and CircuitHub: https://www.youtube.com/watch?v=pweALaGK-W0&t=3s

Nadim Conti:

Linkedin: https://www.linkedin.com/in/nadimconti/en

Website: www.nadimconti.com

Email : info@nadimconti.com

Dugan Karnazes:

https://www.linkedin.com/in/dugan-karnazes/

Website: velocityresearch.co

email: info@velocityresearch.co

OSV Specific email: covid19@velocityresearch.co

Twitter: @Velocity_RD

Instagram: @velocity_research

Facebook: @VelocityResearchGR

Ep.5: The pick and place assembly process

On this week's episode we talk about the pick and place assembly process (which also served as the inspiration for our show name) - the process of placing parts onto circuit boards using automated machines.

-We recap on how we've been adjusting in the factory amidst the continuing pandemic and how we're dealing with some of the growing pains as business starts to boom again.

-We discuss the steps after the parts are kitted that have to be done to get the board ready to be assembled:

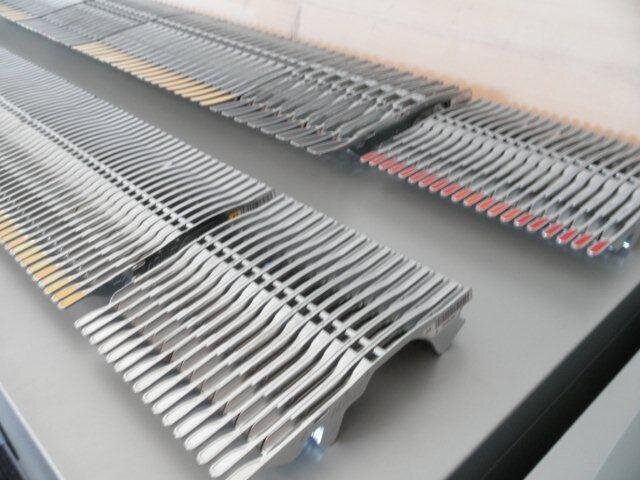

The parts have to be loaded onto a feeder.

Loading an 8mm MyData feeder https://youtu.be/HU88ym0sdEQ

The feeders are placed in a magazine.

Mycronic feeders

Magazine

We briefly discuss the different types of feeders and magazines that are available.

On the Mycronic machines we use, the magazine is what advances the part in the pick and place machine.

MyData magazine advancement mechanism https://youtu.be/5ytCNuvdB2w

-We touch on the environmental impact of different types of equipment.

-Aside from tape and reel some parts come in tubes are trays and need to be loaded differently.

Mycronic stick feeder

-Why is set up one of the most time consuming steps in the whole manufacturing process?

-Once the parts are all loaded on to the machine, we describe the steps that have to be done in order to get it ready to run.

-We talk about the different types tools that are used to pick parts up and place them on the board and the technology that is used to make sure parts are being placed precisely and accurately.

-MyData machine in action https://youtu.be/B_bllEK55JU

-"Chip shooter" style pick and place machine: https://www.youtube.com/watch?v=nah4BQ9y8IY

-"Odd form" style pick and place machine: https://www.youtube.com/watch?v=EUxBMUS45Kg

-We talk things customers can do (and things we would prefer you to avoid) in order to make the pick and place process run smoother.

-On the next episode: We'll be speaking to Dugan and Nadim about their involvement with the Open Source Ventilator project.

Episode 4 - All about parts purchasing - part 2

In part 2 of our episode about parts purchasing with Brett and Magnus from Worthington, we talk about things we think customers should know about the process of purchasing parts and also the topic of parts consignments.

If you’re just tuning it, make sure to listen to part 1 first.

In part 1 we discussed what Magnus and Brett do for Worthington and CircuitHub, questions customers frequently ask us about parts and purchasing, and recommendations we have for customers.

This week we’re talking about things we think customers should know about the process of purchasing parts and also the topic of parts consignments.

Show notes

Attrition

-What is attrition and why is it required?

-Different reasons for attrition - reader attrition caused by loading the feeders vs attrition caused by the machine.

-How do we decide how much attrition to buy for each part?

Purchasing for production

-Purchasing parts for a prototype order vs production order?

-Parts discounts for multiple repeat production orders.

-What is the process of getting custom quotes for parts?

-How does quantity affect lead time?

-How are parts affected when scaling from prototype to production volume?

-What is involved from the part vendor’s perspective to get parts picked and delivered?

-Options for parts that are going out of stock that are critical components?

Consignments

-What scenarios do customers choose to have us consign parts rather than having us buy them?

-Best practices for sending parts to your manufacturer.

-Deadlines for sending consigned parts.

-Why don’t we like to accept fully consigned kits?

Ep. 3: All about parts purchasing - part 2

Intro

-This week we are joined by Brett and Magnus from Worthington to talk about parts and parts purchasing.

-Brett and Magnus give us a brief overview of what they do at Worthington and what they did before joining Worthington.

-We reflect on a twelve pound circuit board we are making and some of the challenges that come along with building something so big!

-Brett and Magnus discuss the differences in the part buying process for Worthington vs CircuitHub.

-How has COVID-19 affect parts purchasing and shipping?

Questions from customers

-Why is this out of stock?

-Why is my order held up? (What causes delays in delivering a product to a customer?)

-Why are these parts more expensive than when we previously bought them?

-We talk about how tariffs on parts get handled and billed (it’s not as simple as you might think).

-What is markup and why does it exist?

Recommendations to customers

-Use parts that are widely available in the supply chain.

-Speciy alternative parts that can be substituted whenever possible.

-Keep the lifecycle of the part in mind when designing your board - don’t use parts that are obsolete or nearing their EOL.

-Keep MOQs in mind.

-Small decisions early on can have a huge impact later on.

-Avoid using parts from hobbyist website - they are great for your personal projects but are not designed for professionally produced products.

-Be very careful (and sometimes suspicious) of buying parts from unauthorized distributors.

-Ask us if there’s anything different that they could do to improve the purchasing process?

Up next

We’ll continue the second half of the conversation in the next episode to discuss this things we wish customers knew and the whole subject of consignment.

Ep 2. The pcb assembly process

On this episode, Chris Denney gives us an overview of the assembly process, everything that happens after you place an order until when your boards are shipped.

Show outline:

We discuss the difference between placing an order at Worthington vs CircuitHub.

The three first steps happen in conjunction: Gerber data is submitted to begin board fab, the BOM is verified and purchased, the Gerber data and XY data is used to program the machines that will be assembling the boards.

These first three steps typically begin within the first 24 hours of submitting an order.

The board fab shop does a CAM process that verifies that your design is actually manufacturable.

The fab shop will send us an array file, which has the individualized design panelized that allows us to assemble the design automatically via machines.

The array data is used to program the stencil printer, pick and place machine, selective solder machine and AOI machine.

The BOM is purchased only from authorized distributors and customers send us any consigned parts.

After the parts come in they go through a kitting process.

Once the parts, bare boards and stencil are kitted they are released to the floor to be assembled.

The surface mount team loads the job onto the pick and place machine feeders.

Wet, tacky solder paste is printed onto the boards using the stencil.

The boards and parts are loaded onto the pick and place machine where the vacuum tools on the machine will suck up the parts and place them onto the machine.

Solid solder joints are created by running the board panels through a reflow oven.

The boards then go through AOI (automated optical inspection) which determines whether the parts are there and if they are placed correctly.

If a board is double sided it repeats the whole process.

Through hole parts gets inserted by hand and soldered using a selective solder machine or by hand.

The boards are inspected by humans.

The boards are de-panelized into individual boards.

The boards are wrapped in ESD safe bubble wrap and ESD shielded bags and then shipped.

We've shipped to every continent except Antarctica!

You finally get your boards!

What topics are listeners most interested in learning more about?

On the next episode we'll be talking to Brett from Worthington to talk about part purchasing.

E1: Get to know the show

Join hosts Chris Denney and Melissa Hough as they discuss their involvement with CircuitHub and Worthington. Find out what you can expect to learn on Pick, Place, Podcast.

Welcome to our new show, the Pick, Place, Podcast! On today’s intro episode, join hosts Chris Denney and Melissa Hough as they discuss their involvement with CircuitHub and Worthington. Find out what you can expect to learn on the Pick, Place, Podcast.